Light duty conveyor belt are specialized types of conveyor belts that are designed for applications with minimal load and low impact forces. They are commonly used in industries such as food processing, agriculture, and packaging, where materials are light and require gentle handling. In this article, we will provide an overview of light duty conveyor belts, including their definition, types, and how to choose the right one for your application.

Definition of Light Duty Conveyor Belt

Light duty conveyor belts are typically made from lightweight materials such as PVC, polyurethane, or rubber. They are designed to handle small or lightweight products and have a maximum load capacity of around 50 pounds per square inch (psi). These belts are usually no more than 3 millimeters thick and can be used for horizontal, inclined, or declined conveying.

Types of Light Duty Conveyor Belt

1. Flat Belts

Flat belts are the most commonly used type of light duty conveyor belt. They consist of a flat, smooth surface and are commonly made from PVC or rubber materials. Flat belts are ideal for transporting lightweight items such as small packages, boxes, and parcels.

2. Incline Belts

Incline belts are used to transport materials up inclines or to higher levels in a facility. They are made with a textured material, such as rubber or PVC, to provide grip and prevent items from slipping. Incline belts are commonly used in industries such as farming, mining, and construction.

3. Modular Belts

Modular belts are made up of interlocking plastic or metal modules that create a flat surface for the product to move along. These belts are commonly used in industries where the product being transported needs to be visually inspected, such as in the food and beverage industry. They are also ideal for packaging and sorting applications.

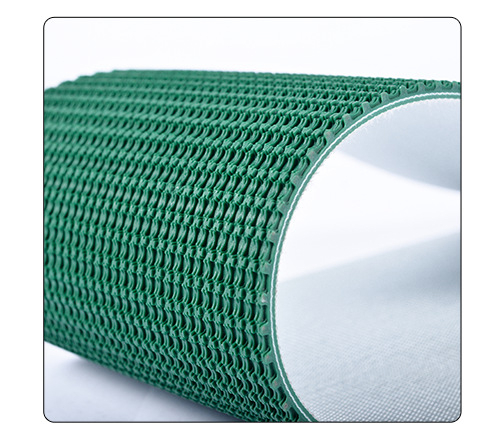

4. Rough Top Belts

Rough top belts have textured surfaces that provide grip and prevent items from slipping. They are commonly used for transportation of lightweight items on inclines or declines. Rough top belts are often made from PVC or rubber and are used in industries such as agriculture, construction, and packaging.

How to Choose the Right Light Duty Conveyor Belt?

1. Consider the Product

The first step in choosing the right light duty conveyor belt is to consider the product that will be transported. Different products have different weight, size, and texture, which can affect the choice of conveyor belt. For example, flat belts may be suitable for small lightweight items, but inclined belts may be better for larger, heavier products.

2. Determine the Load Capacity

Light duty conveyor belts have a maximum load capacity of around 50 psi. It is important to determine the weight of the heaviest product that will be transported to ensure that the conveyor belt can handle the load. This will also help in choosing the right type of belt, as some are better suited for heavier loads than others.

3. Evaluate the Operating Conditions

The operating conditions, such as temperature, moisture, and chemical exposure, can also affect the type of light duty conveyor belt that is suitable for your application. For example, if the conveyor will be used in a wet or humid environment, a PVC or rubber belt with a textured surface may be more suitable to prevent items from slipping.

4. Consider the Speed and Direction of Movement

Another important factor to consider is the speed and direction of movement of the conveyor belt. Modular belts may be better suited for high-speed applications, while rough top belts are more suitable for inclined movement.

5. Consult with Experts

Lastly, it is recommended to consult with experts in conveyor belt systems to ensure you choose the right one for your specific application. They can provide valuable insights and recommendations based on your needs and help you find the most suitable light duty conveyor belt.

light duty conveyor belts are specialized types of conveyor belts that are designed for lightweight and low-impact applications. When choosing the right one for your application, it is important to consider factors such as the product, load capacity, operating conditions, speed and direction of movement, and consult with experts for their expertise and recommendations. With the right light duty conveyor belt, you can improve the efficiency and productivity of your operations while ensuring the safety and gentle handling of your products.

Our low friction light duty conveyor belt is specially designed to reduce the energy consumption and noise levels of your conveyor system. Made from premium synthetic rubber with a special low friction coating, this belt offers smooth and quiet operation, making it ideal for use in retail, warehouse, and distribution applications. Its superior abrasion resistance and excellent grip also ensure efficient and reliable material handling. With a wide range of sizes and customization options available, our low friction conveyor belt is a cost-effective solution for your lightweight conveying needs.

1.Are there any special handling instructions for light duty conveyor belts?

Yes, it is important to handle light duty conveyor belts with care to avoid any damage or twisting of the belt. It is also important to store the belts in a clean, dry environment to prevent deterioration.

2.Can a light duty conveyor belt be spliced or joined together?

Yes, light duty conveyor belts can be spliced or joined together using various methods, such as vulcanization or mechanical fasteners. This allows for longer lengths of belt and can provide better functionality for certain applications.

3.Can a light duty conveyor belt be used for incline or decline conveying?

Yes, light duty conveyor belts can be used for incline or decline conveying, as long as the angle is within the belt's recommended limit and proper grip on the belt is maintained.

4.Can a light duty conveyor belt be used for heavy duty applications?

No, light duty conveyor belts are not suitable for heavy duty applications. They are designed for lighter loads and may not be able to withstand the weight and stress of heavy materials.

5.Are there any safety features to consider when choosing a light duty conveyor belt?

Yes, some light duty conveyor belts may have safety features such as anti-static properties, flame-retardant coatings, and high-friction surfaces to prevent material slippage.

6.Can a light duty conveyor belt be used for manual sorting or packing?

Yes, light duty conveyor belts can be used for manual sorting and packing, as long as the materials being handled are within the belt's weight limit and proper safety precautions are followed.