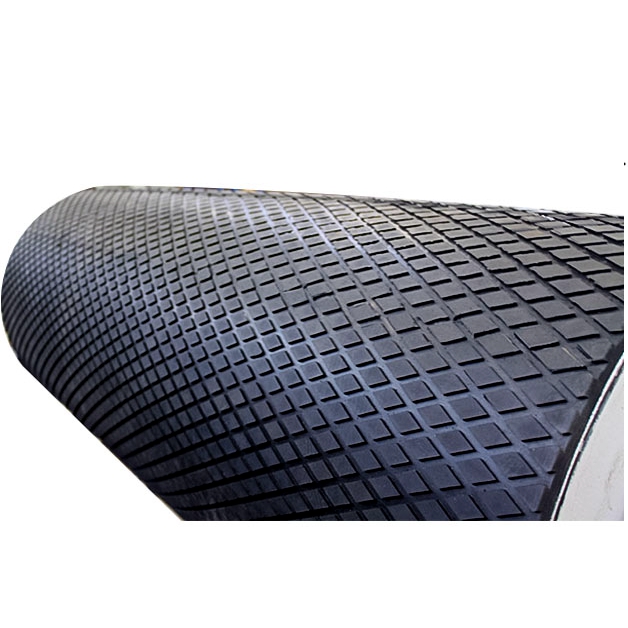

Rubber pulley lagging is made of high-quality rubber material that resists wear, tear and other forms of damage. It improves the friction and traction between the pulley and the belt. This helps prevent the belt from slipping on the pulleys, which can damage the belt and pulleys and cause costly downtime.

Advantages

*CN Bonding layer

*Easy to install

*Minimum wastage and economical price

*Increased friction coefficient between the drum and belt

*Shorter lead times

*High wear resistant

Standard Product Sheet

Property | Value |

Thickness | 8mm to 30mm |

Width | 1000/1200/1450/2000mm |

Hardness (Shore A) | 65+/-5 |

Density (g/cm³) | 1.35/1.3/1.25/1.2/1.15 |

Tensile Strength (MPa) | 6/8/10/12/15/18 |

Elongation (%) | 250/300/350/400/420/450 |

Tear Resistance (N/mm) | 25/25/30/30/35 |

Abrasion Resistance at 5N (mm³) | 350/300/250/200/150 |

Compression Set after 22h at 70℃ (%) | 50/45/40/35/30 |

Work Temp (℃) | -40 to 90 |